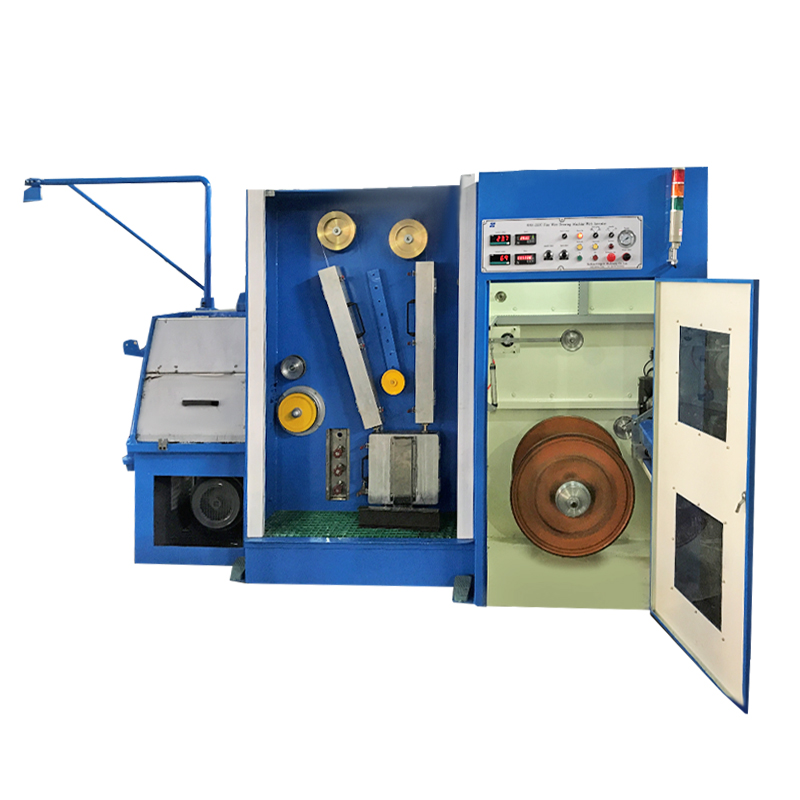

| Machine type | HXE-22DH | HXE-14DH |

| Control system | Motor analog type (push-button type) | |

| Inverter control | Dual inverter control | |

| Outlet diameter | Φ0.1-Φ0.5 | Φ0.25-Φ0.8 |

| Inlet diameter | Φ0.8-Φ1.6 | Φ0.8-Φ2.0 |

| Max.line speed | 2000mpm/max | 1500mpm/max |

| Die number | 22 | 14 |

| slip ratio of m/c | 15%+8% | 15%+8% |

| Final slip ratio | 0%-2% | |

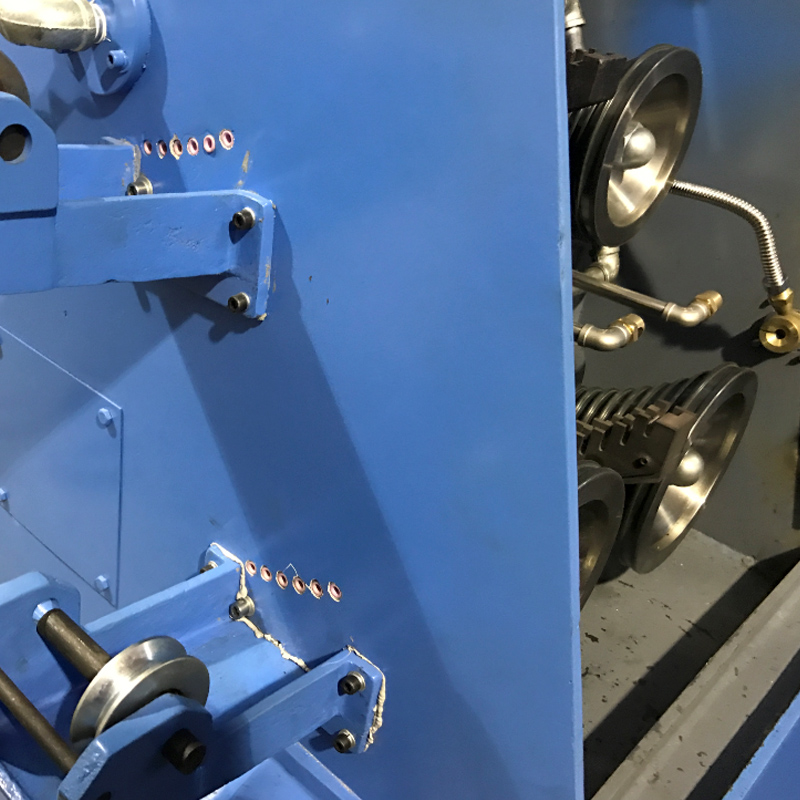

| Frame | Iron plate welding annealing treatment | |

| Capstan | Adoption of ceramic or tungsten carbide spools | |

| Max.capstan diameter | Φ242mm | Φ315mm |

| Fix speed capstan diameter | Φ200mm | Φ223mm |

| Spooler bobbin size | O.D.Φ630mm/Φ500mm | O.D.Φ630mm/Φ500mm |

| Bobbin loading&unloading type | double end thimble | |

| Traversing unit | Motor type | |

| Main motor | 15KW | 18.5KW |

| Spool motor | 15KW | 15KW |

| Transmission type | Flat belt + V-belt | |

| Revise system | PID Variable Position Detection for automatic winding control | |

| Detecting device | Cylinder swing arm buffer bar | |

| Tension control | Adjustment of air pressure | |

| Max.loading capacity | 5ooKG/MAX | 5ooKG/MAx |

| Brake | Disc brake | |

| Lubrication type | Sprinkler-type | |

| Power source | 38oV 50/60Hz | |

| Lubrication capacity | 60 liters per minute | |

| Dimension | 2400*1352*1970 | 2530*1350*2050 |

| Weight | 3800KG | 4200KG |

-

02.22

In modern industry, wire drawing technology has a wide range of applications, from jewelry manufacturing to cable production, to the manufacture of high-end electronic equipment, each link is insepara...

-

02.15

In the field of wire and cable manufacturing, technological innovation is the key force driving the development of the industry. Among them, High Speed Bunching Machine, or high-speed bunching machi...

-

02.08

In the field of modern industrial manufacturing, aluminum has become an indispensable material for many industries such as wire and cable, aerospace, and automobile manufacturing due to its light weig...

-

02.01

In the modern electrical and electronic industry, copper wire is the core of conductive materials, and the optimization of its performance is directly related to the quality and efficiency of the prod...

-

01.22

In modern manufacturing, the production of fine and ultra-fine wires plays an important role. With the continuous advancement of science and technology, the demand for wires has become more and more d...

-

01.15

In the modern wire and cable manufacturing industry, Rod Breakdown Machine plays a vital role. This equipment provides key raw materials for multiple industries such as electronics, automobiles, and e...

-

01.08

In the field of metal processing, Super Fine Wire Drawing Machine plays a vital role. This equipment has become an indispensable tool for the production of ultra-fine metal wires with its high precisi...

-

01.01

In the vast landscape of modern manufacturing, advancements in material processing technologies have consistently driven industries towards greater efficiency and environmental sustainability. Among t...

-

12.22

In modern manufacturing, efficient and precise mechanical equipment is the key to improving production efficiency and product quality. Especially in the field of wire and cable manufacturing, Multi He...

-

12.15

In modern manufacturing, Super Fine Wire Drawing Machine has become an indispensable and important equipment in many industrial fields due to its high precision and versatility. This type of machine n...

-

12.08

In modern industrial manufacturing, aluminum is widely used in aerospace, transportation, construction, electricity and other fields due to its light weight, corrosion resistance and good thermal cond...

-

12.01

In the rapidly developing modern industry, efficient, precise and automated production equipment has become a key factor for enterprises to enhance their competitiveness. Especially in the wire and ca...